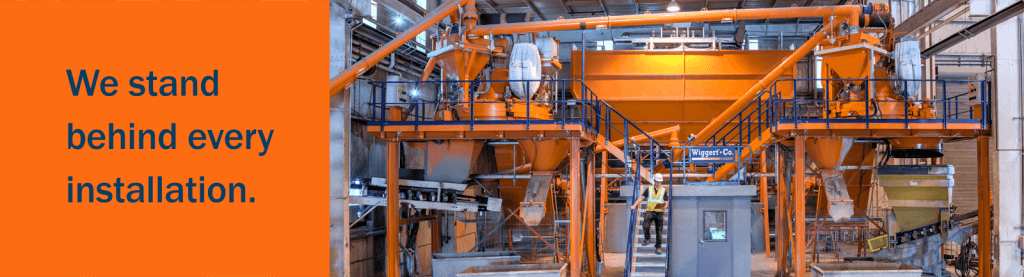

Concrete Color Metering Systems

Quality, accuracy, and ease of use are what the world has come to expect from concrete color metering systems engineered by our partner, Wuerschum GmbH. Whether you use powder, granule or liquid pigments to feed single or multiple production lines, ACT’s color metering systems provide solutions that ensure precise metering for consistent concrete colors.

Powder

Our precision TFW and PW Color Pigment Metering Systems are ideal for weighing small quantities of all concrete pigment powder types. The PW system electronically weighs up pigment powder and discharges by gravity into the mixer. The TFW system accurately weighs the color recipe and then slurrifies the color batch with water for rapid, dust free dispensing into a concrete mixer up to 300 ft. away. They can be outfitted with weighers sized to measure 10lb (5kg) up to 220lb (100kg) color batches, and multiple discharge hoppers for instant delivery to multiple mixers. Best of all, these systems use labor saving large quantity Super Sack bags of pigment powder and can be installed at ground level, so loading can be done easily and quickly with a forklift.

Color Pigment Metering System FLEX 70

Pigment powder or granular pigments can all be metered with the new FLEX 70 color metering system from Wuerschum GmbH. The FLEX 70 gives you the independence to select the best deal possible from any reputable pigment vendor.

The FLEX 70 provides accurate, fast pigment metering with pneumatic conveying of the pigment batch to up to three mixers. Using four primary color pigments, an unlimited number of color shades are possible. An extra color dispensing position is available for special colors. An additional extra Super Sack rack may be added to double the storage capacity of certain, high use pigments.

The FLEX 70 color metering system comes factory-tested and pre-wired with all electric and pneumatic wiring. A mixer dust collection system is available and includes reverse air shock for automatic filter cleaning.

Key Advantages of the TFW and FLEX 70 Color Metering Systems:

- Accurate and fast metering with special screw conveyors

- Coarse and fine metering of pigment

- Dust free pigment delivery into the mixer

- FLEX dust collection system with reverse air shock filter cleaning

- For Super Sack or paper bags (50 lb / 25 kg)

- Unlimited number of color shades possible

- Distribution to multiple mixers

- Extra position for special colors available

- Remote positioning of the system at ground level

Granule

COM Granule Concrete Color Pigment Metering Systems

Versatility and accuracy in a compact design are hallmarks of our COM 30 and COM 70 Granule Concrete Color Pigment Metering Systems. They feature fast, accurate and virtually dry, dust-free batching for both C and G grade granule pigments. These systems are ideal for added value Colormix products since virtually any color shade can be produced from only 3-4 primary colors and pre-weighed for on-demand dispensing into the concrete mixer. Our COM systems are so fast that one single COM 70 color metering station can serve up to 3 different production lines simultaneously with no wait on color to the concrete mixer.

Key Advantages of the COM Systems:

- Versatility, able to meter compact or granule type pigments

- Dust free batching

- Short cycle time (2.2lb/sec metering)

- Separate conveying pressure pod for each mixer (COM 70)

- Coarse fine metering for superfine accuracy

- Rugged industrial support frame

- Pneumatic conveying allows remote location of COM system

- COM 70 allows for pre-weighed batching for fast cycle time

- COM 70 pressure pods prevents contamination

- COM 30 low profile design

G-Pac 30 Automatic Color Metering Systems

G-Pac is a clean and accurate solution for automatic pigment metering. It offers affordable, fast, accurate color metering for ready mix and concrete producers.

Key Advantages of the G-Pac 30 System:

Universal:

- Accurate metering into dissolvable bags or buckets

- 4 primary colors can create unlimited custom blends

- Custom colors on demand

Easy to Use:

- PC based automatic control system

- Small footprint can service multiple plants

- Improves plant cleanliness

Performance:

- Precision electronic weigh hopper

- Top quality reliable equipment

- Lowers plant operating costs

Quality Control:

- Each batch is recorded

- Inventory usage tracking

- Provides color consistency

G-Pac 30 Automatic Coloring System

Liquid

Assortments of custom liquid weighing dispensers are available. Liquid dispensers are an economical alternative for systems where only occasional colored batches are made and the annual pigment consumption is limited.

Mixing tanks for on site slurry preparations are suitable for users with a high yearly consumption rate (i.e. roof tile manufacturers), providing them with the flexibility to select the best deal possible for powder pigments.