Concrete Batching and Mixing Products

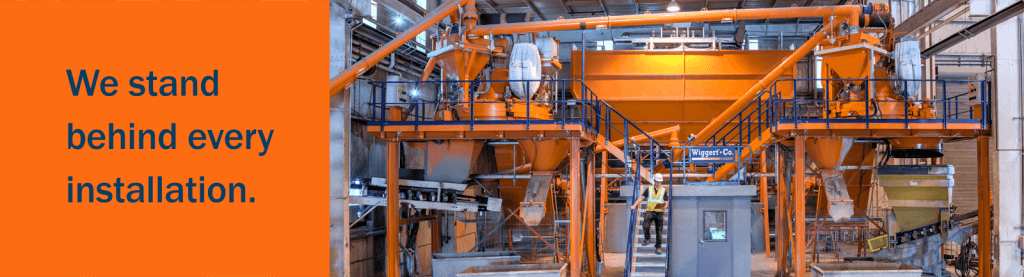

Our success is based on proven German engineered components, reliable control technology and a commitment to turnkey solutions and exceptional customer service. We are a single-source supplier of turnkey concrete batching plants and mixing solutions that supports all concrete products industries.

ACT specializes in projects where a consistent superior quality concrete is required (i.e., factory made, wet cast, dry cast, and colored concrete products). Our concrete equipment and plant designs provide maximum reliability, along with the flexibility that allows concrete producers to be up and running faster. ACT delivers complete solutions to add profitability to your mix.

Concrete Batching Plants and Concrete Equipment:

WiCoMix Concrete Batch Plant

ACT's concrete batching and mixing plants are the industry's best turnkey solution designed to get your concrete batch plant running and profitable as quickly as possible and producing the highest quality concrete with the least amount of hassle. Completely pre-assembled, pre-wired, pre-plumbed and factory tested and de-bugged before shipping, our plants are the guaranteed way to rapid on-site set-up and start-up of your concrete mixing and concrete batching plant operations.

More on ACT's Turnkey Concrete Batching and Mixing Plants

MobilMat Concrete Batch Plant

A versatile concrete batch plant & mixing plant for a wide range of applications, these concrete batch plants range in concrete output capacities from 20 – 160 yd3/hr. MobilMat concrete batching plants are available as single or multi-mixer turnkey solutions. Completely pre-assembled, pre-wired, pre-plumbed and factory tested before shipping, MobilMat guarantees rapid set-up and start-up.

More on ACT's Turnkey Concrete Batching and Mixing Plants

CentroMix Affordable Precast Solution

CentroMix is an affordable precast and on-site solution. With our CentroMix plants, higher-quality, consistent concrete is not only possible, it's profitable!

More on ACT's CentroMix Affordable Concrete Batching Plant

Twin-Shaft Concrete Mixer - DWM

DWM twin-shaft mixers are ideal for the ready-mix and precast concrete industries where large volumes of high quality concrete are demanded. The powerful twin-shaft mixer, with counter rotating shafts, delivers fast mixing action and rapid discharge and handles mix designs with large aggregates. The rugged DWM has low operating costs and is available in 5 sizes.

More on ACT's Twin-Shaft Concrete Mixers

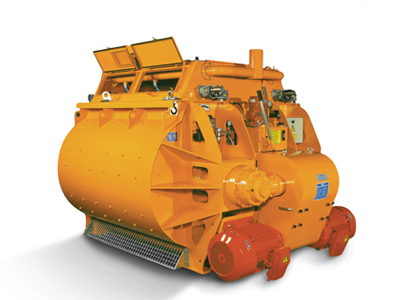

Planetary Countercurrent Concrete Mixer - HPGM

Delivering the highest quality homogenous concrete mix possible, in the least amount of time, is what our Wiggert HPGM mixer is all about. Standard in 10 sizes, available with multiple discharge gates this mixer has what it takes to be the heart of your business. The high intensity mixing action achieves best cement dispersion and is the hallmark of the HPGM design. The rugged HPGM mixer can handle anything from wet and dry cast concretes, specialty mix designs to the latest self-compacting, ultra-high strength concretes, and much more.

More on ACT's HPGM Concrete Batch Plant System

Concrete Batch Plant Distribution and Delivery - Flying Bucket System

Nothing is more important for high volume, quality concrete products than a constant supply of freshly mixed concrete. Our reliable dual-rail flying bucket systems delivers fresh concrete mix at your concrete batching plant to wherever it's needed for maximum plant efficiency and labor savings.

More on ACT's Concrete Batch Plant Distribution System

Concrete Batching Control System - WCS

Designed for unattended, automatic operation, our WCS Controls operate on a Microsoft Windows 10 platform. The WCS Concrete Batching Control has an intuitive point-and-click control that is simple to use, comprehensive and scaleable. The WCS integrates process supervision, production reporting, inventory tracking, recipe management, plant maintenance, costing functions and more, all in one reliable control system.

More on ACT WCS Concrete Batching Control System

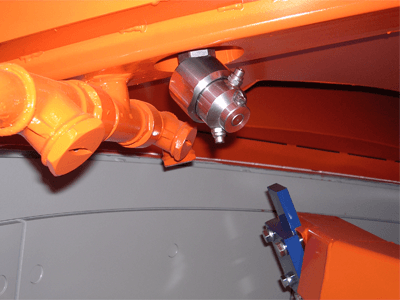

Admixture Metering System

Concrete admixtures require the highest degree of metering accuracy to ensure consistent properties and quality in your concrete mix. No other concrete admixture metering system on the market does it better than our Model AC Admixture Metering System.

More on ACT's Admixture Metering System

Color Pigment Metering System

Quality, accuracy, and ease of use are what the world has come to expect from concrete color metering systems. Whether you use powder, granule or liquid pigments to feed single or multiple production lines, ACT’s color metering systems provide solutions that ensure precise metering for consistent concrete colors.

More on Color Pigment Metering System

HYDROMAT Microwave Moisture Control System

Moisture can be the enemy when concrete batching plant precision is demanded. Thankfully there is HYDROMAT. Fully integrated into our PCS Control system, the HYDROMAT provides accurate computerized microwave moisture measurement and automatically adjusts batch water addition. The HYDROMAT is ideal for applications where absolute consistent concrete product quality is required (i.e. dry-cast, pigmented concrete, etc.).

More on HYDROMAT Microwave Moisture Control System

HYDROTESTER II Moisture Control System

Our HYDROTESTER II moisture probes are available for use in aggregate bins for accurate concrete batch yield and correction due to varying moisture in the raw materials. This probe uses SONO/Sonar technology to accurately determine the total moisture content of the material flowing across the ceramic face. It measures both free and absorbed moisture value. The PCS control will then use this value to adjust the yield to account for the moisture present and dose the "dry weight" of the material being measured.

More on HYDROTESTER II Moisture Control System

Automated Mixer Cleaning System for Concrete Batch Plants

The inevitable, dirty job of concrete mixer cleaning is now faster and more cost-effective than ever before with our Automated Mixer Cleaning System. Key advantages of the 3D high pressure spray geometry include water conservation and shortest cleaning times to extend your production day. With the push of a button you can have faster, safer cleanout, happier personnel, labor savings, and better maintained equipment.

More on Automated Mixer Cleaning System

EcoClean Waste Water Treatment Plant

EcoClean, the new waste water treatment plant from ACT is available in several models with a capacity of 1,000 gallons a day and up. The waste water is purified by the use of a decanter system and a filter press, optionally the purified water can be pH adjusted.

More on EcoClean Waste Water Treatment Plant