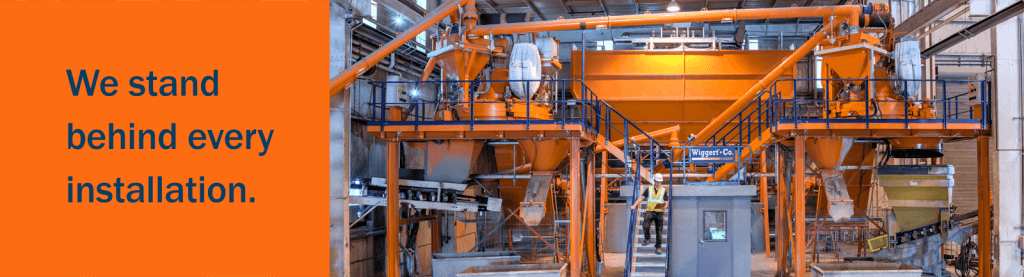

Turnkey Concrete Batching & Mixing Plants

ACT's concrete batching and mixing plants are the industry's best turnkey solution designed to get your concrete batch plant running and profitable as quickly as possible and producing the highest quality concrete with the least amount of hassle.

Completely pre-assembled, pre-wired, pre-plumbed and factory tested and de-bugged before shipping, our plants are the guaranteed way to rapid on-site set-up and start-up of your concrete mixing and concrete batching plant operations.

All you have to do is provide foundations and single point air, power and water connections prior to delivery and set-up. You can virtually eliminate unexpected construction problems and unforeseen cost overruns that could potentially delay your start-up date and blow your project budget. Your project will come in on time, on budget, and you'll be producing top quality concrete from the first concrete batch.

Concrete Batch Plants with Custom Options

Our concrete batch plants can be configured with your choice of automated controls, from the basic STC system to our industry leading WCS controls which provides detailed recipe-based settings and statistics reporting capabilities that can be custom tailored to your business needs. In addition, all electrical components, including all the motor starters for the entire concrete batch plant, are integrated into our control cabinet. All that’s needed is a single on-site power connection. All of the batch plant's electrical field wiring is CSA/UL compliant.

Other available options include our Automatic Mixer Cleaning System for faster and safer cleanout, labor savings, and extended production time. If colored concrete is required, a fully automated pigment metering system (liquid, powder, or granule) can be integrated into the concrete batch plant and control system.

ACT's concrete mixing and batching plants can be configured with HPGM planetary counter-current mixers or with DWM twin-shaft mixers depending upon your application. Additional mixer discharge gates (HPGM mixers only) or multiple mixer configurations are also available to maximize production output capacity or to serve multiple production lines. The mixer can be fitted with our HYDROMAT Automatic Microwave Moisture Metering technology, giving you absolute consistent water/cement ratio control every concrete batch.