Breaking News!

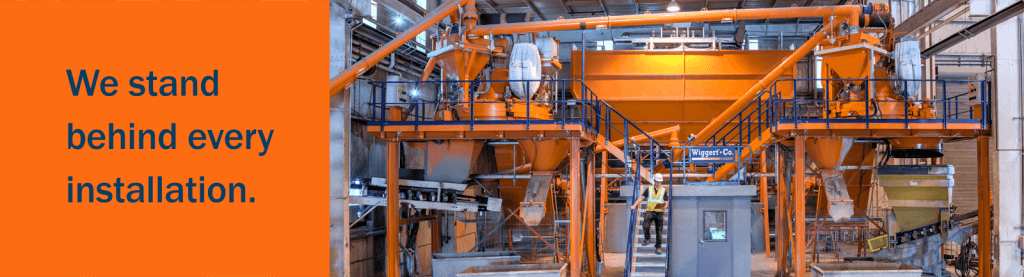

Advanced Concrete Technologies, Inc. enters 2017 with a new line of affordable batch plants equal to a wide range of applications. The small footprint CentroMix models arrive on site pre-wired, pre-plumbed and factory tested for quick and easy installation—requiring merely a single electric, water and air connection to be up and running.

The CentroMix design suits a variety of plant types, including conventional and architectural precast plus dry cast production. Its portability also suits onsite concrete production. The CentroMix is available in a range of flexible layout options and expandable as a producer grows.

ACT offers the plant in two sizes: ½-yd. or 1-yd. output with high performance planetary CPM Wiggert Mixer, which features large access doors with standard safety locks and premium efficient drive for quiet operation. Among other key plant features:

- Cumulative aggregate weighing system provides precision batching for up to four aggregates;

- Aggregate bins can be configured for charging by a front-end loader, or as forklift-transferred exchangeable bins for specialty aggregates;

- Optional automatic Hydrotester moisture correction for each aggregate bin;

- Precision weigh batcher handles up to three cementitious materials;

- Control for up to four admixtures, with factory-mounted mixer inlets available;

- Totally enclosed mixer for virtual dust free batching;

- Galvanized, perimeter safety guarding; and,

- Available skid mount frame to eliminate need for foundation

The CentroMix is also equipped with a hydraulic mixer discharge gate, and batches water volumetrically, which performs a mixing tool rinse each load. Standard on the  plant is ACT’s user-friendly Control System (CCS), tying together in one efficient package recipe management, production process supervision, available production statistic information, printer and online support. The CCS is delivered fully prewired with integrated Motor Control Center. The PLC-based control system has the capability to store up to 250 recipes and can record every batch made in a CVS file.

plant is ACT’s user-friendly Control System (CCS), tying together in one efficient package recipe management, production process supervision, available production statistic information, printer and online support. The CCS is delivered fully prewired with integrated Motor Control Center. The PLC-based control system has the capability to store up to 250 recipes and can record every batch made in a CVS file.

See complete Concrete News article here